Thermal Design and CFD

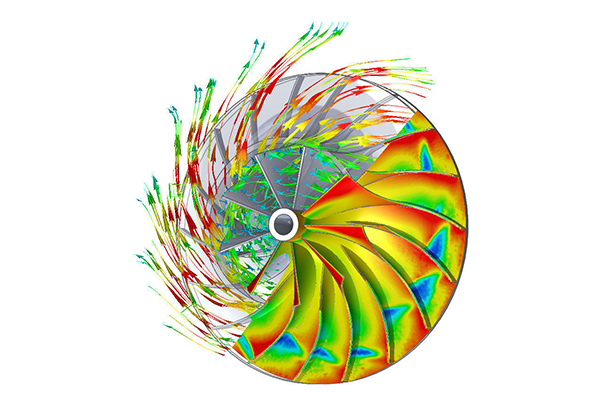

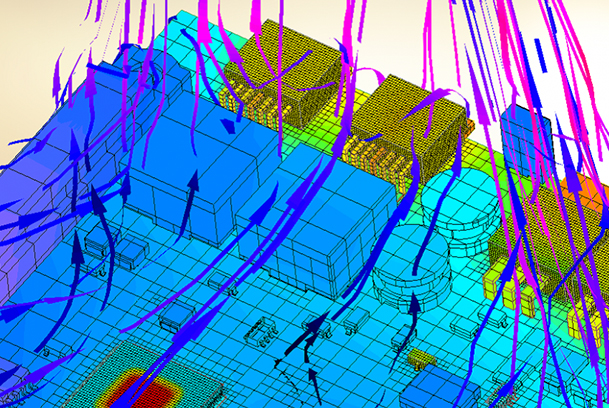

Our in-house, qualified engineers are on-hand to support you from the initial design phase through to mass production. We can model and critique the thermal parameters of your design using Computational Fluid Dynamics (CFD) analysis as well as our own proprietary empirical techniques. This enables us to create functional thermal solutions that meet the demanding cooling requirements of modern electronics in the most efficient and cost-effective way possible.

CFD is employed for complicated thermal problems where it is not possible to manually calculate what the most effective solution might be. After running repeated modelling simulations and varying the input parameters each time it is then possible to optimise the model so that it most closely resembles the desired outcome. A good calculated result in CFD gives extremely high confidence that a real solution will be just as effective. CFD can also be used to identify potential issues or ‘hot spots’ that may occur and cause a problem in terms of reliability and product life.

As well as for new products, we have been engaged by clients on existing products to:

- Design out cost

- Reduce component weights

- Improve thermal performance

For more information on how our design services can benefit you then please Ask Bluecore.

DESIGN SERVICES

- Computational Fluid Dynamics (CFD)

- Computer Aided Design (CAD)

- Weight reduction

- Eliminate fans for a passive solution

- Projected cost of the final product

PROTOTYPING AND TESTING

- CMM and precision measuring tools

- Thermal measurement devices

- Thermal chambers

- Shock testing and cycling

- Salt spray testing for corrosion analysis

MANUFACTURING

- State of the art CNC machinery

- Stringent quality control

- Latest production techniques

- Focus on continuous improvement

- Robust packaging design

10Years of Outstanding Service

33Countries Supplied

52Production Machines

1000Extrusion Profiles

Need Help With Your Inquiry? Our In-House Engineers Are Happy to Help.Ask Bluecore