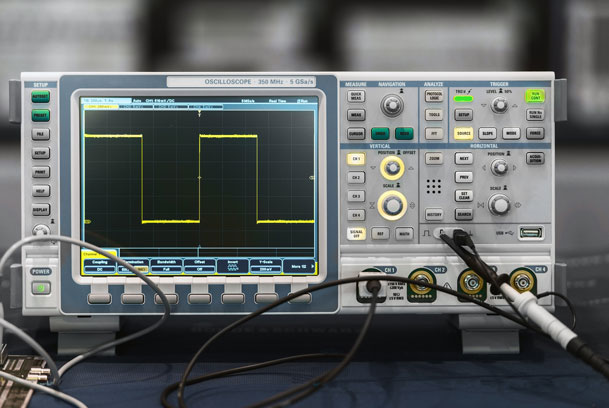

Testing

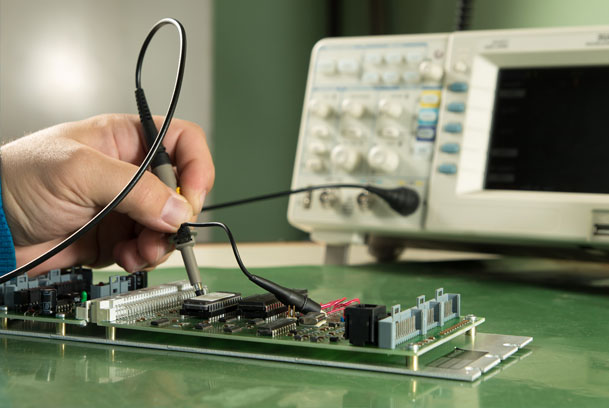

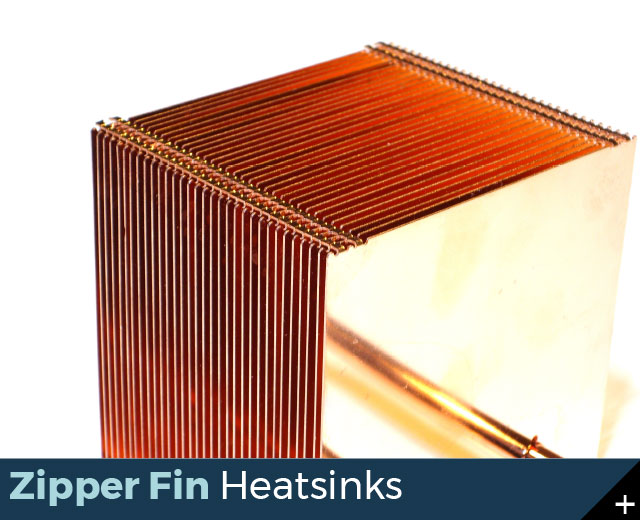

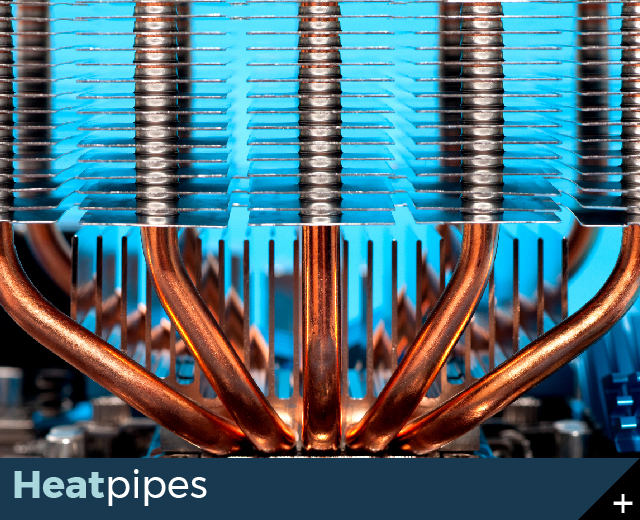

As the capability of modern electronics and processors increase, it has been possible to add more and more functionality to modern test and measurement equipment. This increased power and functionality has come at a price with more heat being created, often in a smaller area, which greatly increases the power densities of these products. This has meant a move towards more advanced cooling solutions, often incorporating heat pipes and active cooling in order to maximise product performance and reliability. This is especially pertinent as the industry takes a more modular approach, delivering a range of upgradeable functionality from a basic test chassis.

Typical applications include hot and cold side heat sinks for Peltier devices, heat transfer using spreader plates or heat pipes, or routing heat to the outer casing for dissipation while maintaining safe touch temperatures. Adding cloud functionality or wifi capability to devices also increases their heat output, which needs to be managed without increasing the size of the products. The thermal design of the outer sheet metal casing and location of perforations can also be key to product performance.

Bluecore have designed thermal solutions for:

- Sample heaters & coolers

- Desk top metrology

- Torque sensors on production lines

- Large scale laboratory equipment

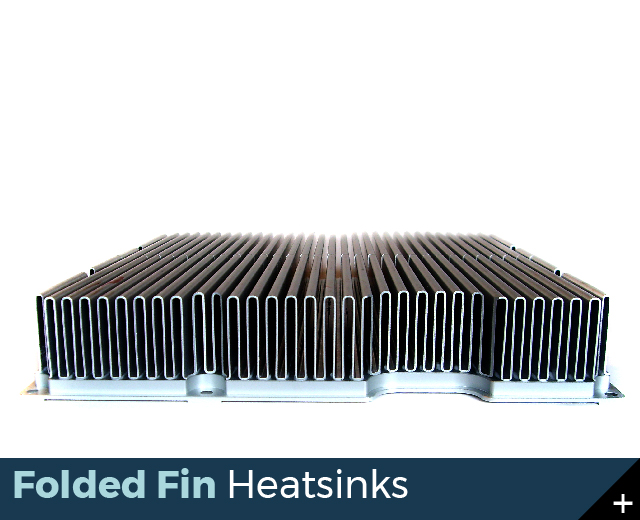

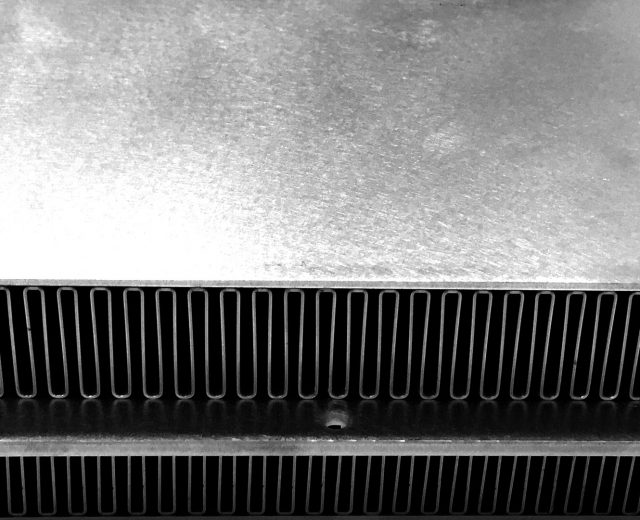

Folded Fin Heat Exchanger

Bluecore has been engaged to manufacture a folded fin heat exchanger for a display application. The display screen will be [...]

Read moreFolded Fin Heat Exchanger

Intelligent TV

As televisions gain greater functionality and begin to offer services more akin to a computer, the processing power is increasing [...]

Read moreIntelligent TV

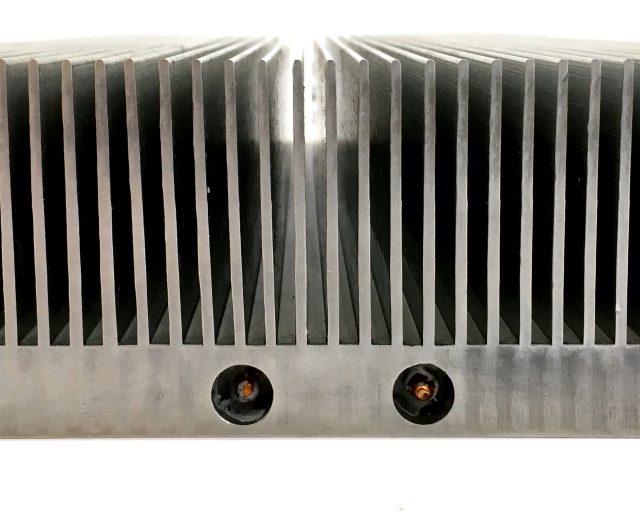

Cool Audio

Bluecore has completed design and supply of a high fin density machined extrusion for a power amplifier OEM. We were engaged early [...]

Read moreCool Audio

Active Sound

Bluecore is now producing extruded heatsinks for a high-end UK manufacturer of active speakers. The heatsinks form part of the [...]

Read moreActive Sound

Advanced Storage

Bluecore are supplying a die cast aluminium USB case to a leading memory and storage OEM. The flash drive can function as a [...]

Read moreAdvanced Storage

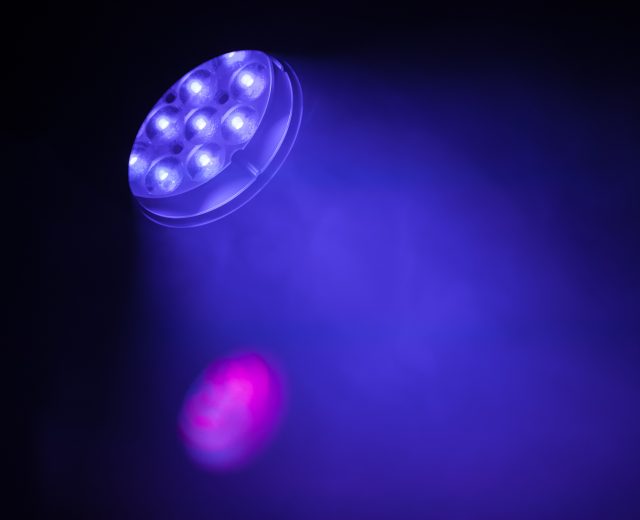

Innovative Design in the Spotlight

Following several years of development, Bluecore are pleased to announce we will be manufacturing event lights for a specialist UK [...]

Read moreInnovative Design in the Spotlight

Bluecore in Front

Bluecore are pleased to announce we are supplying aluminium front panels to a leading OEM for their new amplifier. The front [...]

Read moreBluecore in Front

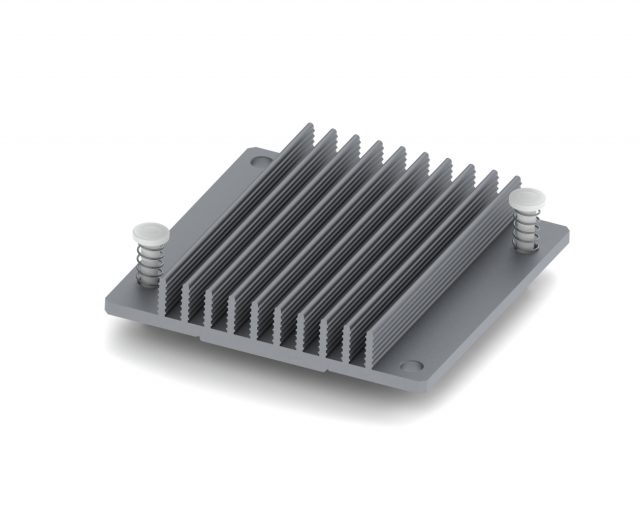

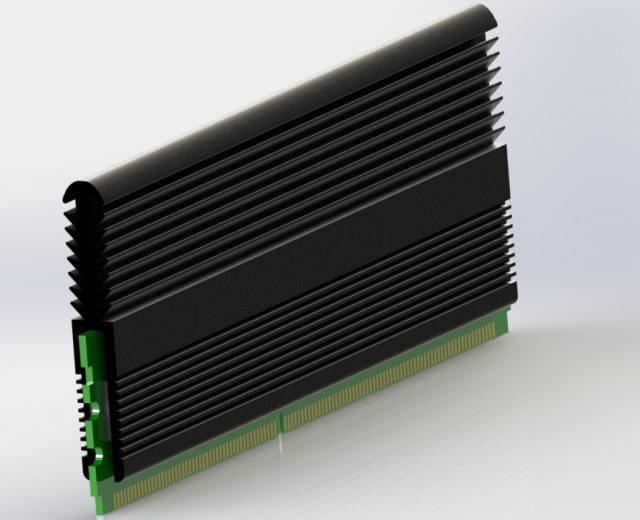

DDR Heat Spreaders

Performance and reliability of DDR RAM modules can be affected by overheating, potentially causing major issues for the platform it is

Read moreDDR Heat Spreaders

Comfort in Flight

We are pleased to announce that Bluecore have been engaged to provide a leading aerospace OEM with machined aluminium arm

Read moreComfort in Flight

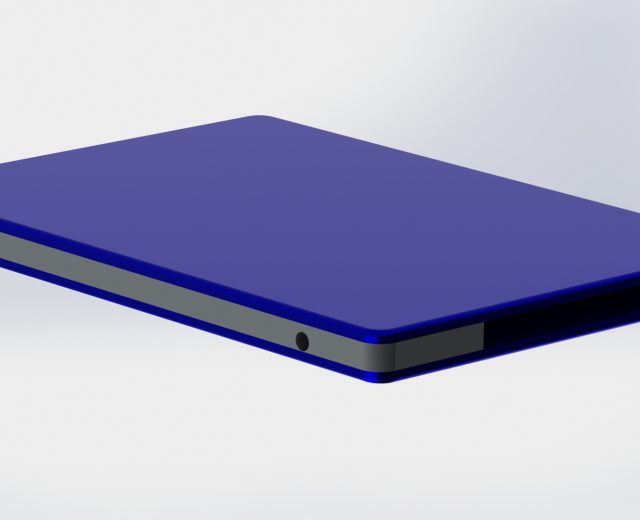

Storage at Speed

Solid state drives (SSDs) have revolutionised the computer market and greatly reduced access time and latency in comparison to [...]

Read moreStorage at Speed

Bluecore Make Housings for Futuristic LED Street Light

Bluecore will be providing large die cast housings for intelligent street light systems to an advanced lighting company based in [...]

Read moreBluecore Make Housings for Futuristic LED Street Light

Cost Effective Quality

Like all consumer applications, the set top box market is defined by its high quality requirements and low cost production. [...]

Read moreCost Effective Quality

Washing Machines Clean Brighter with Bluecore

Bluecore are happy to announce we have been selected to provide a custom extruded heat sink for a washing machine application.

Read moreWashing Machines Clean Brighter with Bluecore

Keeping Cool at Altitude

Bluecore have been engaged to provide custom extruded heatsinks for a battery pack on a private jet,manufactured by a world leading

Read moreKeeping Cool at AltitudeDESIGN SERVICES

- Computational Fluid Dynamics (CFD)

- Computer Aided Design (CAD)

- Weight reduction

- Eliminate fans for a passive solution

- Projected cost of the final product

PROTOTYPING AND TESTING

- CMM and precision measuring tools

- Thermal measurement devices

- Thermal chambers

- Shock testing and cycling

- Salt spray testing for corrosion analysis

MANUFACTURING

- State of the art CNC machinery

- Stringent quality control

- Latest production techniques

- Focus on continuous improvement

- Robust packaging design

10Years of Outstanding Service

33Countries Supplied

52Production Machines

1000Extrusion Profiles

Need Help With Your Inquiry? Our In-House Engineers Are Happy to Help.Ask Bluecore